|

|

product name: | F36 F46 F60 black silicon carbide/ F36 F46 black SIC for cutting wheel |

| Place of Origin: | Peoples Republic of China | |

| Post Date: | March 12, 2021 | |

| Edit Date: | March 12, 2021 | |

Detailed Product Description:

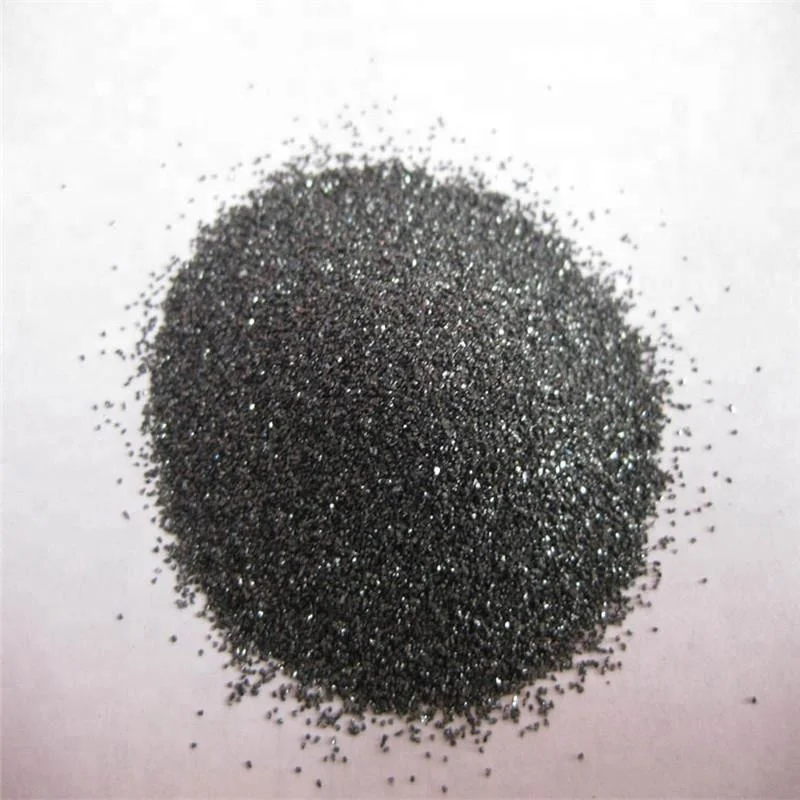

F36 F46 F60 black silicon carbide/ F36 F46 black SIC for cutting wheel

Sillicon Carbide(SIC) is made from quartz sand and petroleum coke(smokeless acetylene) as the mainraw material.it is made via light resistance from hydrometallurgical,it is black opaque body hexagonal crystal and MOHS -hardness in the 915-9.5,which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat.

black silicon carbide is with sic purity 98% and the toughness is higher than green silicon carbide, mainly used for processing glass,ceramic,stone, refractory materials ,cast iron and other metal.

Physical and Chemical Properties:

| Color | Black |

| Mohs Hardness | 9.5 |

| True Density | 3.9g/cm3 |

| Melting Point | 2250°C |

| Maximum service temperature | 1900°C |

|

Properties and Type |

Grains | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Guarantee Value | Typical Value | ||

| Chemical Composition | SIC | ≥98 | 98.5 |

| F.C | ≤0.2 | 0.1 | |

| Fe2O3 | ≤0.2 | 0.15 | |

| H2O3 | ≤1 | 0.3 | |

Products Showroom