|

|

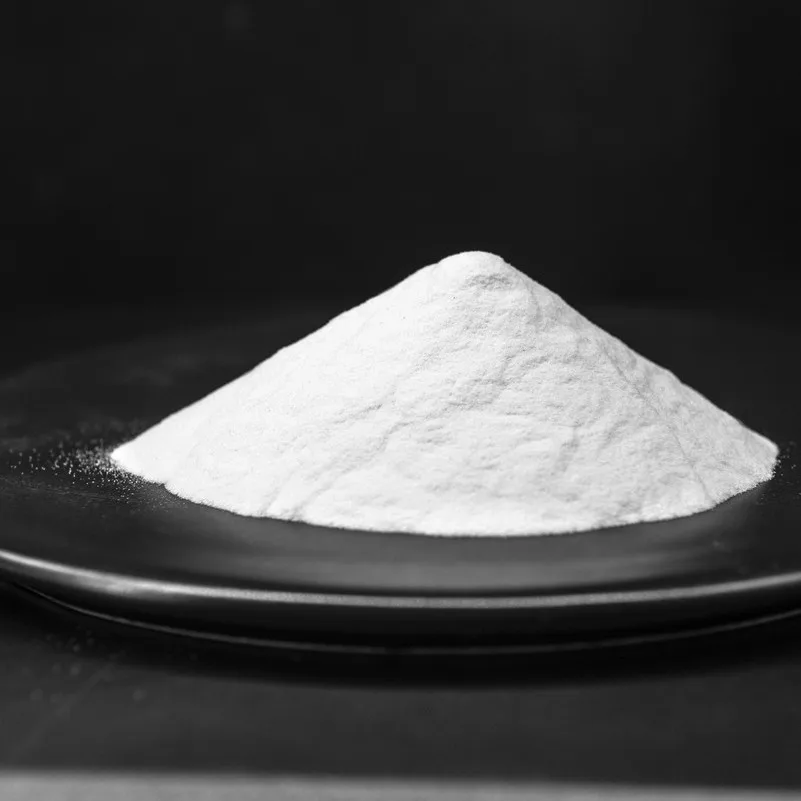

product name: | white corundum powder /white fused aluminum oxide powder for abrasive stones |

| Place of Origin: | Peoples Republic of China | |

| Post Date: | March 4, 2021 | |

| Edit Date: | March 4, 2021 | |

Detailed Product Description:

---Description

The WFA is the main raw material for the production of unshaped and shaped refractory materials.

Commonly used in ladle castables, iron runner materials, refractory gunning mix materials and other monolithic refractory products;

For the shaped refractory materials, it is mainly used in the high-quality raw materials of corundum brick, corundum mullite, refining steel porous plug brick, integral spray gun, steelmaking and continuous casting industry.

It also can be used as materials for polishing, precision casting, spraying and coating, special ceramics

---Processing:

Products Show:

| Chemical Composition | ||

| Al2O3 | ≥99.3% | |

| SiO2 | ≤0.15% | |

| Fe2O3 | ≤0.05% | |

| Na2O | ≤0.30% | |

| Bulk Density g/cm3 | ≥3.50 | |

| True Density g/cm3 | ≥3.95 | |

| Application | Grain size | |

| Abrasive | F | 8#-60# |

| 70#-150# | ||

| 180#-240# | ||

| Refractory | FRACTION | 0-1 mm |

| 1-3 mm | ||

| 3-5 mm | ||

| 5-8 mm | ||

| 8-12 mm | ||

| Fine Powder | 100 mesh | |

| 220 mesh | ||

| 325 mesh | ||

----Advantages

*Refractory Grade

1. white fused alumina has higher hardness and high refractories over 1750℃

2. it is characterised by its high purity acid and alkali resistance

3. good thermal stability

*Abrasive grade

1. It does not affect the color of the workpiece

2. It can be used for sandblasting in the process of prohibiting iron powder residue

3. The micro powder grade is very suitable for wet blasting and grinding and polishing operations

4. It is in fast processing speed

5. The amount of iron oxide contained is extremely low, suitable for sandblasting operations where iron residue is strictly prohibited

---Applications

---Packing